A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

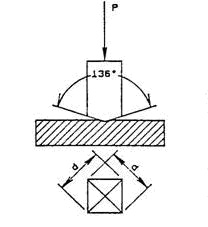

Principle

A constant force is applied on the sample surface with an indenter – typically a Vickers pyramid – in order to create a surface deformation. Then the hardness of the test sample is determined from the load needed to create the deformation and the dimensions of the permanent deformation.

Hv = P/S

Where P is the load applied on the sample surface (kgf)

and S the indentation surface (mm²)

Equipment

Vickers STRUERS Duramin-1

Microhardness tester is equipped with :

![]() 9 types of loads, from 10g to 2 kg (eg HV0,01 to HV2)

9 types of loads, from 10g to 2 kg (eg HV0,01 to HV2)

![]() Two objectives : X10 andX40

Two objectives : X10 andX40

Microhardness measurements are performed very quickly, with high accuracy and reliability, on all types of samples (metals, ceramics, compressed materials, integrated circuits, coatings,…). This equipment also allows observing grain microstructures.