A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

Principle

Optosurf interferometric measurement system is based on Michelson’s interferometer principle (interferences between a reference mirror and the sample’s surface).

The sample is lighted up by a filtered white light source. 50% of the beam is sent on a reference surface (mirror) thanks to a separative slide. The other part lights up the sample’s surface. Reflected beams from the mirror and the sample are combined on the separative surface and interfere.

Height differences between the sample and the reference create a interference pattern related to the sample’s surface.

Those Height differences are recorded and numerically processed so as to reconstruct the surface ( 100 µm²).

Many processings are available : surface characterization, roughness parameters calculation, distances and heights measurements, 3D and 2D representations, …. This system is particularly dedicated to extra-polished surfaces.

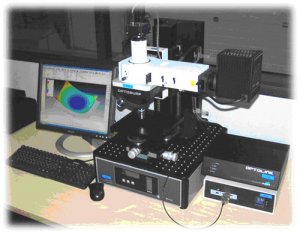

Apparatus : OPTOSURF measurements station

Principle

A light beam from an halogen lamp (polychromatic white light) passes through an optic fiber and goes to a passive probe. This passive probe has a chromatic aberration lens that divides the beam into monochromatic wavelengths on a z range (300 µm or 3mm, as a function of the probe). As a function of the surface’s relief, some wavelengths are reflected, other don’t. Reflected wavelengths are then interpreted in terms of height.

Surface treatment processing

Surface state characterization

![]() Normalised 2D and 3D roughness parameters calculations

Normalised 2D and 3D roughness parameters calculations

![]() Distances, heights, angles and thickness measurements

Distances, heights, angles and thickness measurements

![]() Volume measurements (peaks or valleys)

Volume measurements (peaks or valleys)

![]() 2D and 3D surface representation

2D and 3D surface representation

Applications : surface characterization on all types of supports, tribology, coatings control, defects propagation (ex : cracks, scratches,…), surface planeness, manufacturing control, etc.

Apparatus : Station ALTISURF 500

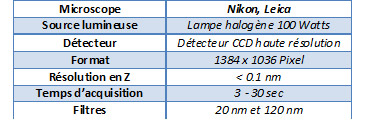

Technical Characteristic :

![]() Speed maximal : 10 mm.s-1

Speed maximal : 10 mm.s-1

![]() Probes : 300 µm (résolution 0,01 µm) et 3 mm (résolution 0,1 µm)

Probes : 300 µm (résolution 0,01 µm) et 3 mm (résolution 0,1 µm)

![]() Table Precision : inférieure à 0,1 µm / 50 mm

Table Precision : inférieure à 0,1 µm / 50 mm

![]() Measure up to 43 ° angle

Measure up to 43 ° angle