A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

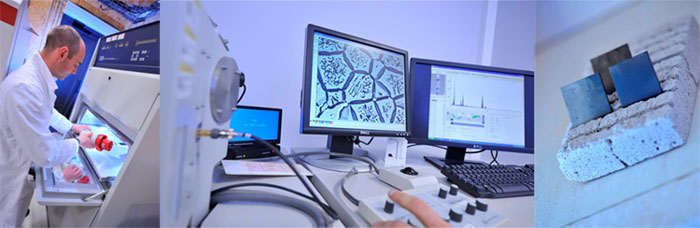

The ANALYSES & SURFACE laboratory has set up a joint CEVIMAT laboratory created with the Materials Physics Group (GPM) to obtain synergies between a leading university laboratory and a CRT organized to meet the needs of industry in terms of quality, cost and lead-time.

The CRT serves as a front office for exchanges with industrials and supervise the joint project with the GPM, and provide a response based on fundamental (State of the Art) studies for the industrials’ technical applications across the entire value chain, while sharing a team of teacher-researchers, PhD graduates and engineers and a highly efficient installed base of research facilities.

The central theme of CEVIMAT research is the aging of materials and their long-term development. That development is inseparable from the wear properties of the materials, their durability and the dependability of the structures or systems for which they are used.

The CEVIMAT is currently supervising two CIFRE PhD theses involving two regional companies:

The development of an internal diffusion barrier based on a diffusive reaction mechanism in titanium alloys,

The second relates to the improvement of mold coating performance characteristics.

CLIPFAM : Characterization of the Powder Bed for Metal Additive Manufacturing

Metal Additive Manufacturing represents a key technology due to its advantages (integration of functions, production of complex parts, etc.). A new area of research and development of interest in France is that of the characterization of raw materials, namely metal powders. Normandy has strong skills around additive manufacturing with a positioning of players in several segments of the AM value chain: Product design, Material development, Implementation, Product control.

Metal Additive Manufacturing represents a key technology due to its advantages (integration of functions, production of complex parts, etc.). A new area of research and development of interest in France is that of the characterization of raw materials, namely metal powders. Normandy has strong skills around additive manufacturing with a positioning of players in several segments of the AM value chain: Product design, Material development, Implementation, Product control.

The objectives of the work of the CLIP-FAM project are:

![]() * Develop a method for characterizing the scalability of metal powders for additive manufacturing (test bench)

* Develop a method for characterizing the scalability of metal powders for additive manufacturing (test bench)

![]() * Strengthen scalability modeling in order to anticipate optimal production

* Strengthen scalability modeling in order to anticipate optimal production

![]() * Evaluate the impact of a powder with good / bad spreadability on the part produced

* Evaluate the impact of a powder with good / bad spreadability on the part produced

![]() * Support the emergence of a specific powder standard (scalability component)

* Support the emergence of a specific powder standard (scalability component)

Support level: 109,377.60 EUROS over 3 years

CRIOS : Chiller Solution For On-Board Electronic Components In Harsh Environment

The CRIOS project aims to achieve a proof of concept for the integration of existing Phase Change Materials (PCMs) into an electronic system / component to optimize its thermal behavior during large transient power demands.

PACMAN : New Materials For Aeronautical Tanks

Analyses et Surface is part of the PACMAN project for the selection of materials to be used for tank applications for ZODIAC AEROSAFETY SYSTEMS by films to allow an integration of function and therefore ultimately a lightening of the tanks. The study carried out at CRT Analyses et Surface concerns the resistance to aging of the material and the physico-chemical expertise of the materials. The procedure reports on the characterization of specimens before, during and after aging.

Analyses et Surface is part of the PACMAN project for the selection of materials to be used for tank applications for ZODIAC AEROSAFETY SYSTEMS by films to allow an integration of function and therefore ultimately a lightening of the tanks. The study carried out at CRT Analyses et Surface concerns the resistance to aging of the material and the physico-chemical expertise of the materials. The procedure reports on the characterization of specimens before, during and after aging.

Support level: 154,885 EUROS over 3 years

THESIS : THermoplastic Erosion Shield for new generation Ice protection System

The THESIS project is part of the goal of optimizing performance and limiting energy consumption, which the aeronautics sector is constantly researching. This project, led by Zodiac Aerosafety Systems, consists of eliminating the high temperature and high pressure air intake from the engines and replacing it with the generation of electrical energy. Through the selection and characterization of thermoplastic materials and the validation of de-icing performance by wind tunnel tests, the challenge is to develop a new technology for electrical or electro-mechanical de-icing on the leading edges of aircraft wings.

The THESIS project is part of the goal of optimizing performance and limiting energy consumption, which the aeronautics sector is constantly researching. This project, led by Zodiac Aerosafety Systems, consists of eliminating the high temperature and high pressure air intake from the engines and replacing it with the generation of electrical energy. Through the selection and characterization of thermoplastic materials and the validation of de-icing performance by wind tunnel tests, the challenge is to develop a new technology for electrical or electro-mechanical de-icing on the leading edges of aircraft wings.

THESIS is thus part of an approach with the study and maturing of a disruptive technology from an energy consumption point of view called pneumo-expulse.

Support level: 132,000 EUROS over 3 years

SIEMSTACK : Electrical Interposer Solutions for a Stacker Module

SIEMSTACK involves the design and manufacture of an innovative electrical interconnection solution for the aeronautics industry. The solution studied in this project is designed to electrically connect parallel circuit boards (PCBs) or ceramic multi-chip-type components (MCM) in a small volume subject to high thermal stress.

REDISPERSE : The environmental impact of the aging and degradation of nanostructured materials

The REDISPERSE project is ultimately designed to study the environmental toxicological impact of the degradation of nanostructured materials.

The scientific objective of the project is to determine whether the wear and aging of nanostructured materials can lead to the release of nanoparticles into the environment. And if that were the case, what would the consequences be of the dust produced (as aerosols or aqueous media) from a toxicological point of view. To do this, exposure will be based on the use of bivalve molds.

RITA : Innovative Repair of Aeronautical Nozzles

The purpose of the RITA project is to develop innovative solutions for the repair of aeronautical nozzles made of titanium alloy. The main technological challenge is to develop a titanium alloy repair process that enables the return to service of the structures for a new aircraft life-cycle.

These projects are co-financed by the European Union, the French government and the Haute-Normandie regional council. The participation of the European Union in Haute-Normandie is through the European Regional Development Fund.

Related article : Innovation and Development Projects

Partner : GPM