A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

For several years, the ANALYSIS ET SURFACE laboratory has been carrying out fluid susceptibility tests according to EUROCAE ED-14G RTCA DO-160 Section 11 (Fluids Susceptibility) or other standards in different sectors of activity (Example: NF ISO 28121, standard VOLVO 1026.8177 or Renault Nissan RNES-B-00090 v2.0 D49 3253

Our resources allow us to take charge of large resistance of coatings to fluids with our immersion and spray possibilities.

The behavior of coatings, treatments or materials in contact with regular fluids in use requires appropriate tests. These materials are subjected to temperatures which will constrain the materials and the service life.

The validation and performance of susceptibility tests in the laboratory according to the normative references in force is therefore an essential step in qualifying a choice of treatment or coating.

These tests are carried out at temperature according to the technical description requested in the customer and CDC specifications, we are equipped with climatic ovens and cycle chambers which can be adjusted as desired which can allow us to test up to very high temperatures ( +400°C) but also at negative temperatures (down to -80°C).

Our flexible capacities also allow us to implement specific cycles in temperature, humidity, UV, in a saline or polluted atmosphere to meet specific specifications to be implemented.

At the end of these tests, we are equipped for the characterization and resistance of paints and coatings according to standards:

• Photos according to NF ISO 4628 or NF ISO 10289 and Light booth,

• Optical microscopy,

• Colorimetry according to NF ISO 7724,

• Gloss according to NF ISO 2813,

• Scratches according to NF ISO 1518,

• Abrasion resistance by the TABER method,

• Grid (Scratch Test) according to NF ISO 2409,

• Adhesion according to NF ISO 4624,

•…

• Fuels (Diesel, Gasoline, BioFuel, Kerosene, JetA, etc.)

• Hydraulic fluids

• Brake fluid

• Lubricating oils (Engine, gearbox, etc.)

• Solvents and cleaning agents (Isopropyl alcohol, Trichlorethylene,…)

• Coffee, Soda, ...

• De-icing fluids (De-icing, Ethylene Glycol, SAE, etc.)

• Insecticides

• Disinfectant

• Fire extinguishers

• Electric fluids (Batteries)

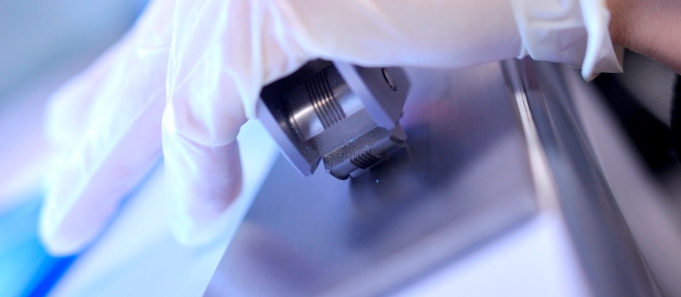

We test many materials (Plastics, Minerals, Steel, Stainless steel, Aluminum, Magnesium, Titanium,…) and coatings / treatments (PA66 paint, SURTEC, ALODINE, Nickel,…).

The results of these tests are used to validate the processes and choices, to qualify your suppliers or to determine the resistance of new materials or treatments.

These tests are carried out in compliance with the standards applicable for many sectors including aeronautical and automotive transport (EUROCAE ED-14G RTCA DO-160 Section 11 (Fluids Susceptibility), NF EN ISO 2812-1, VOLVO 1026.8177 or Renault Nissan standard. RNES-B-00090 v2.0 D49 3253).