A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

This type of defect can pose a risk to the reliability and strength of the materials. Understanding corrosion phenomena enables manufacturers to control the risks in relation to the relevant technical and economic issues.

The capacity to implement the aging tests and analyze the corrosion phenomena involved is a specific feature of the Analyses & Surface laboratory.

The appearance of traces of corrosion can be a sign of premature aging of a part. Many physico-chemical interactions can be the cause of corrosion. The rigorous understanding of the cause of corrosion allows us to implement optimal preventive and / or corrective actions to counter the aging of assemblies or sub-assemblies.

Corrosion defect analysis can be used on all types of materials to:

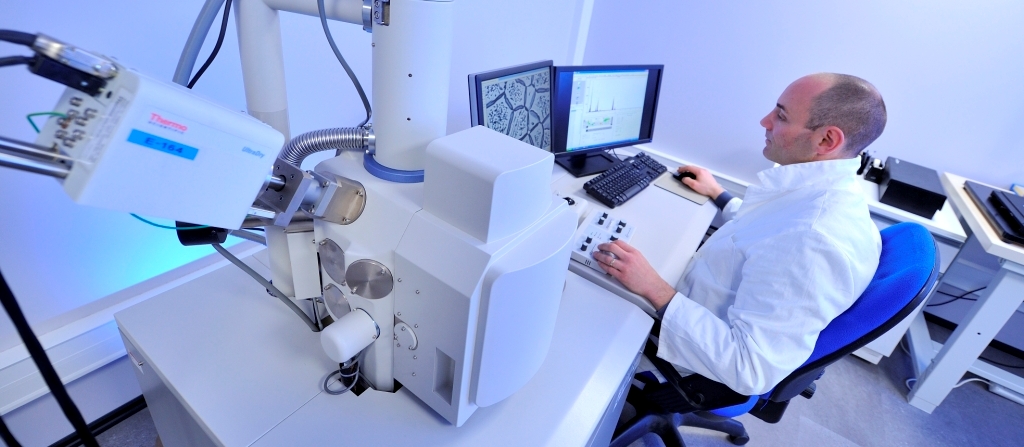

• Observe the nature of corrosion traces on the surface and in the core of the material by optical and electron microscopy;

• Check the conformity of the material used By chemical analysis and characterize its microstructure,

• Confirm the presence of a surface treatment by glow discharge spectrometry (GDMS);

• Determine the type of corrosion (pitting, galvanic, crevice, exfoliation, threadlike, due to stress, hydrogen embrittlement, intergranular, selective, fretting, hot corrosion, etc.);

• To seek the cause of corrosion.

Exfoliation corrosion

Degradation at the base of an aluminum post