A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

The failure of a material, part or structure can lead to many economic consequences for an industrialist. When a failure occurs, it is important to identify its nature and origin in order to set up corrective actions.

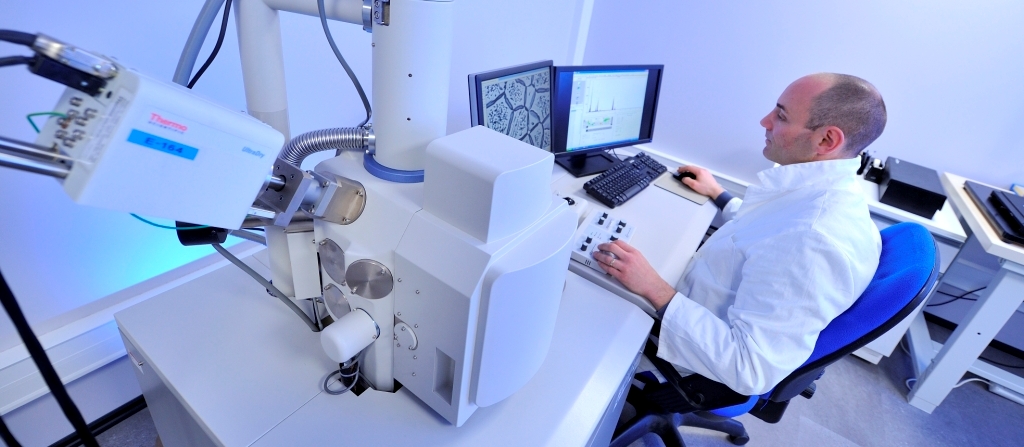

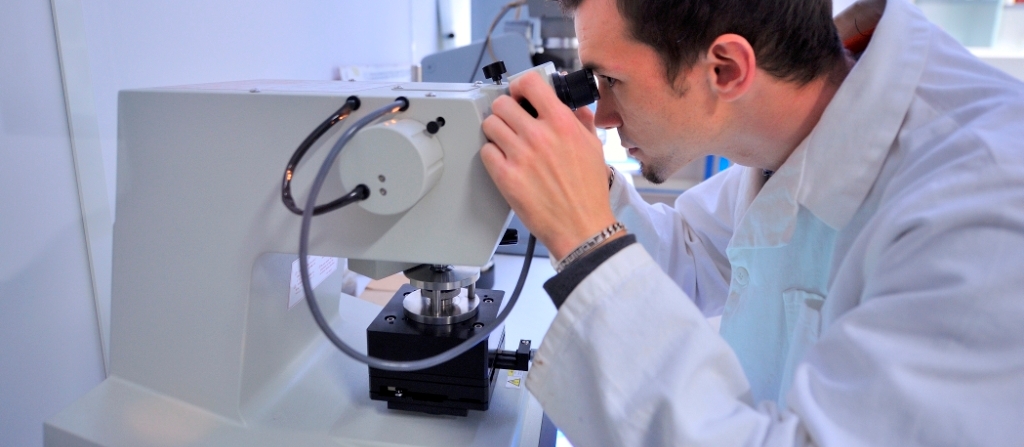

The laboratory’s skills in failure analysis allow us to carry out a full investigation using our high-performance test facilities. Our long-standing experience allows us to highlight indications as to the origin of a failure.

Failure analysis enables us to:

• Check the compliance of the material with the requisite specifications and in-situ constraints by carrying out chemical analyses, mechanical tests and characterization tests of the microstructure;

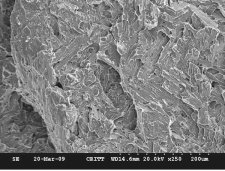

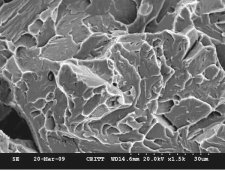

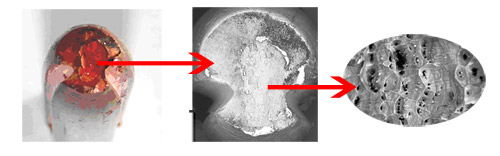

• Observe the fracture surface under microscope to determine the type of failure (ductile, brittle, following a shock, fatigue, material non-compliance, intergranular, intergranular, due to the presence of inclusions, hydrogen embrittlement, etc.);

• Diagnose the cause of the failure and propose solutions.

Our experts can also carry out fractographic analyses on-site.

Ductile fracture

Copper wire with a ductile-type fracture.

Brittle fracture

Screw broken due to excessive tightening torque.