A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

Glass is a material apart, discovered thousands of years ago. Our knowledge about it, as well as the capacity to analyze it and carry out a failure analysis are more recent. Like every material, it is important to know the characteristics of glass materials and enamels as part of assembly control, of both the container and content as well as in cases of defects or failures.

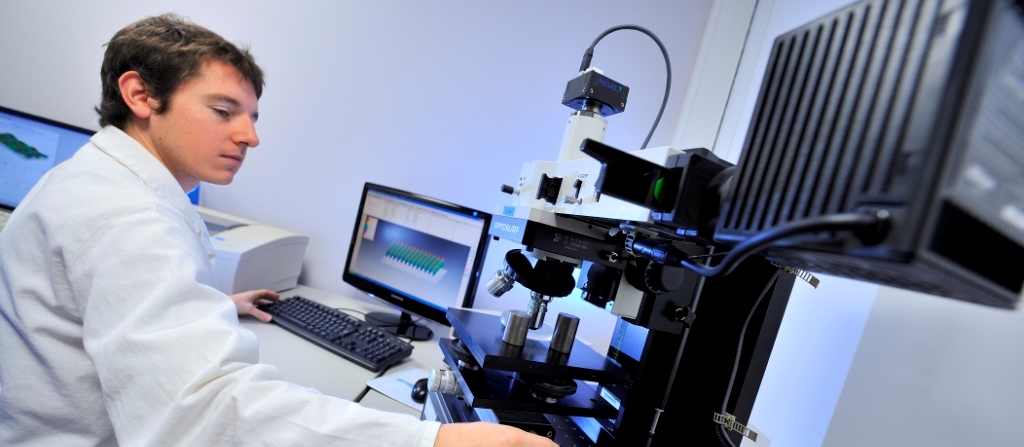

The Analyses & Surface laboratory supports manufacturers (via innovative and efficient technological means and specific human skills) in complete investigation procedures in the field of glass making (analysis, control, failure analysis, etc.).

Glass surface :

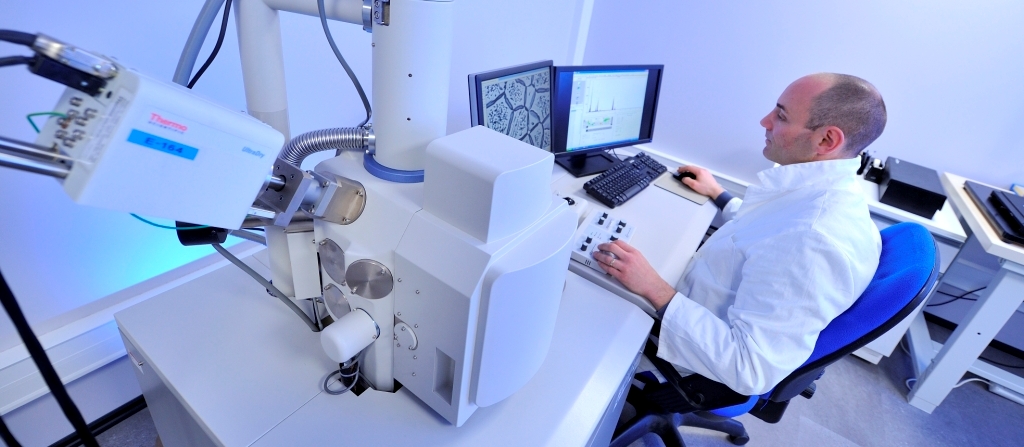

![]() Research / Identification of a surface treatment (SEM-EDX, IR)

Research / Identification of a surface treatment (SEM-EDX, IR)

![]() Physico-chemical characterization of a surface treatment (SEM-EDX, IR)

Physico-chemical characterization of a surface treatment (SEM-EDX, IR)

![]() Characterization of a pollution (SEM-EDX, IR)

Characterization of a pollution (SEM-EDX, IR)

![]() Study of the topography (relief, roughness) of the surface (Non-contact measurement stations)

Study of the topography (relief, roughness) of the surface (Non-contact measurement stations)

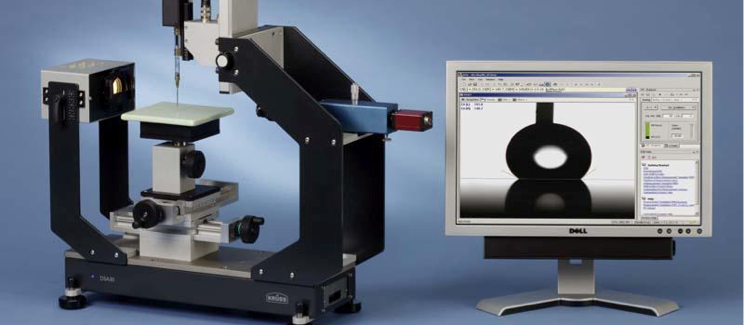

![]() Characterization of the surface tension (Tensiometer, surface energy)

Characterization of the surface tension (Tensiometer, surface energy)

Identification of foreign objects of the glass type

![]() Customer feedback (optical microscopy, SEM-EDX)

Customer feedback (optical microscopy, SEM-EDX)

Characterization of inclusions in the glass

![]() Crystalline inclusions (SEM-EDX)

Crystalline inclusions (SEM-EDX)

![]() Gaseous inclusions (Optical microscopy)

Gaseous inclusions (Optical microscopy)

![]() Vitreous inclusions (Optical microscopy)

Vitreous inclusions (Optical microscopy)

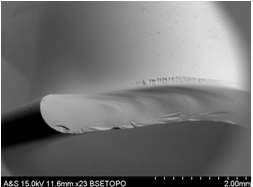

Fractographic failure analysis of a product

To explain the cause of the breakage: localization of the origin and the constraints having caused the failure (Optical microscopy, SEM-EDX)

Checking the dimensions of finished products in relation to the design drawings

Non-destructive study of interfaces in complex systems

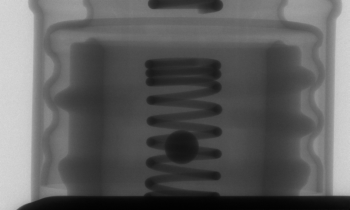

![]() Finding a leak path in a glass vial / plastic sprayer system (X-ray microtomography)

Finding a leak path in a glass vial / plastic sprayer system (X-ray microtomography)

Study of a phenomenon of fissuring of a thread of a glass bottle during ring screwing

Study and design failure

Fractographic failure analysis

Determination of the origin of the breakage of a flange of a glass syringe