A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

A private laboratory specialized in the analysis, testing and failure analysis of materials since 1993

Knowing the morphology and dimensioning of parts, surface layers, paints, or grains... is critical for controlling an industrial process. It is therefore important to know or control these parameters in order to validate the methods used in their production.

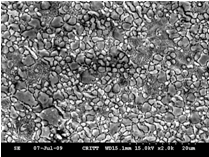

• Microscopic observations of the morphology of powders or materials,

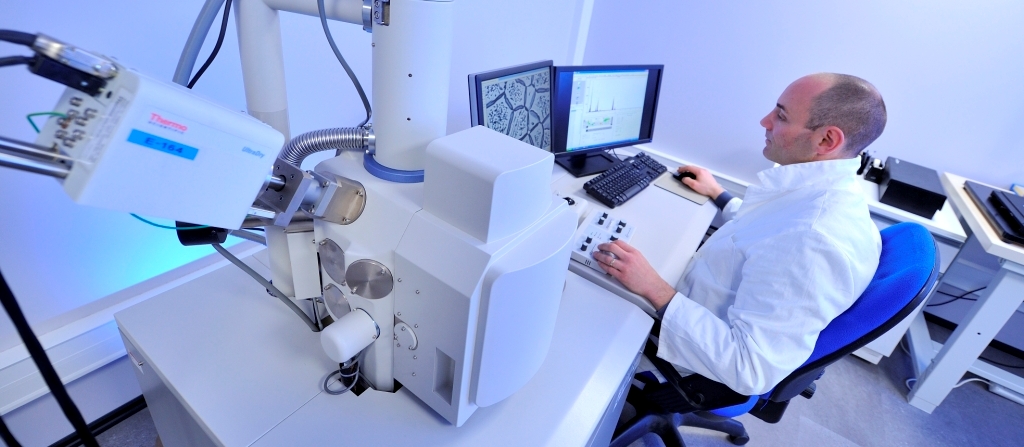

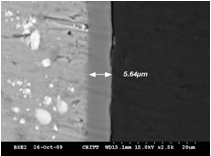

• Macroscopic and microscopic surface and cross-sectional dimensional measurements,

• Observation of the microstructure and Measurement of grain size,

• Characterization of visual defects (bumps or hollows, size, morphology)

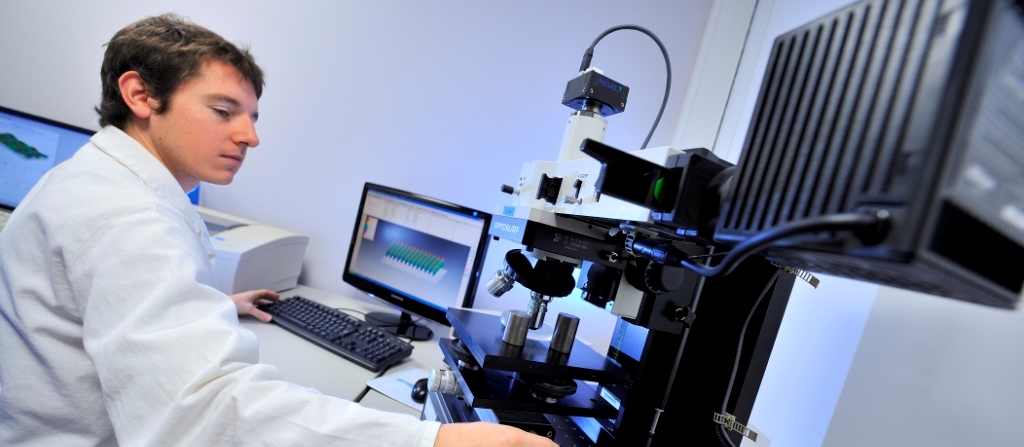

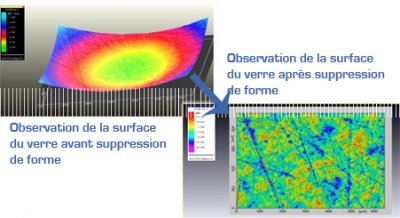

• Surface condition and Roughness (Ra, Rt, Rq, etc.) by non-contact surface topography,

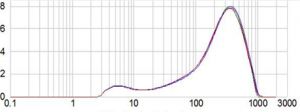

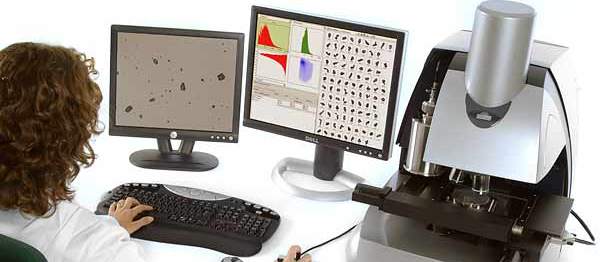

• Characterization of the size of particles in powders or liquids by laser granulometry,

• …

Dimensional characterization of surface treatment

Surface and cross-sectional characterization by SEM

Control of the roughness parameters (Ra, Sa, Rq, Sq, Rt, St, Rz, etc.) on an optical glass

Determination of roughness parameters and characterization of the surface condition

More about ...

Analysis of the particle size of a powder

Determination of particle size distribution and analysis of particle shape